Stunning Tips About What Is SMD

The Basics Of SMD And SMT A Comprehensive Guide Vicoimaging™ Machine

What Exactly is SMD? Let's Demystify It!

1. Unpacking the SMD Acronym

So, you've stumbled across the term "SMD" and now you're scratching your head, wondering what it is. Don't worry, you're not alone! SMD stands for Surface Mount Device. Think of it as a tiny technological marvel, a miniature component that's revolutionizing electronics as we know them. Its quite literally reshaping the landscape of circuit boards.

In essence, SMDs are electronic components that are mounted directly onto the surface of a printed circuit board (PCB). This is a departure from older technologies where components had leads (those little legs) that were inserted through holes in the board. These components have no leads or short leads or terminations on the body of the component. Less is more in the world of electronics. This might seem like a small change, but it has huge implications for the size, performance, and manufacturing process of electronic devices.

Imagine building a Lego castle. Old-style components are like using big, clunky bricks with pegs that only fit into certain holes. SMDs are like using smaller, smoother bricks that can be attached directly to the surface, allowing for more intricate and compact designs. This translates to smaller, lighter, and more efficient electronic devices. Think of your sleek smartphone — packed with features, yet incredibly slim. SMDs are a big reason why thats even possible!

Forget intricate wirework and hole-punching theatrics. Instead of threading wires through pre-drilled holes (tedious, right?), SMDs get cozy right on top of the PCB surface. This streamlined approach means faster production times, reduced manufacturing costs, and a whole lot less opportunity for things to go wrong during assembly. It's like going from handwriting a novel to typing it on a computer faster, cleaner, and way easier to edit.

What Is A Surface Mount Device Or SMD Component Package? JHYPCB

Why are SMDs Such a Big Deal? The Advantages

2. Small Size, Big Impact

Okay, so SMDs are small. But what exactly does that small size get us? A whole heap of advantages, actually! Firstly, the reduced size allows for much higher component density on circuit boards. This means you can pack more functionality into a smaller space. Think about those tiny earbuds that deliver crystal-clear audio — without SMDs, theyd be the size of grapefruits!

Secondly, SMDs often offer improved electrical performance. Because the connections are shorter and more direct, there's less signal interference and better overall efficiency. This is especially important in high-frequency applications, like those found in wireless communication devices. It's like shortening the distance between your router and your computer to get a faster internet connection — less distance, better performance!

Thirdly, surface mount technology (SMT) — the technique of using SMDs — allows for automated assembly. Machines can quickly and accurately place SMDs onto PCBs, leading to faster production times and lower manufacturing costs. Robots are doing the work, which is always pretty cool. This also leads to consistency, meaning fewer errors and higher quality products.

Also, the reduced weight of SMD components is a huge win. Lighter devices are easier to handle, transport, and use. Think about the difference between carrying a heavy laptop and a lightweight tablet — the difference is substantial, and SMDs contribute significantly to this weight reduction.

Types of SMD Components

3. From Resistors to Microchips

SMDs come in all shapes and sizes, each designed for a specific purpose. The most common types include resistors, capacitors, inductors, diodes, and transistors. Resistors control the flow of electricity, capacitors store electrical energy, inductors resist changes in current, diodes allow current to flow in one direction only, and transistors act as switches or amplifiers.

Then you have integrated circuits (ICs), often called chips, which are complex SMDs containing millions or even billions of transistors. These are the brains behind many electronic devices, processing information and controlling various functions. From your computer's processor to the memory chips in your phone, ICs are essential components of modern electronics.

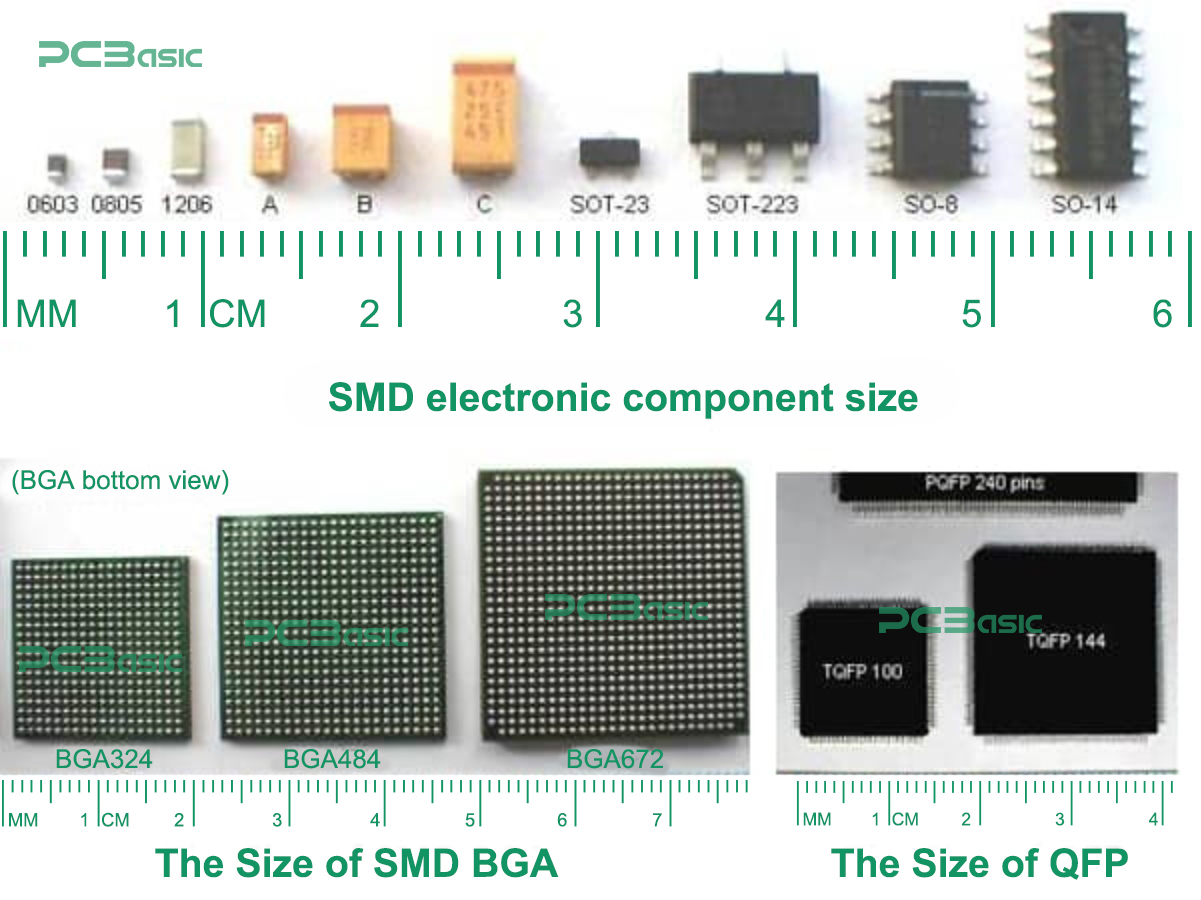

The physical size of an SMD is usually indicated by a code, such as 0603 or 0805. These numbers refer to the dimensions of the component in inches (hundredths of an inch, specifically). So, an 0603 component is 0.06 inches long and 0.03 inches wide. The smaller the number, the smaller the component — and the trickier it can be to handle!

Recognizing these different SMD types can be helpful when troubleshooting or repairing electronic devices. However, working with SMDs requires specialized tools and skills due to their small size. Unless you're experienced in electronics repair, it's best to leave SMD work to the professionals. We dont want any accidentally-fried circuits, do we?

Where are SMDs Used? Everywhere!

4. From Smartphones to Satellites

Okay, so we know what SMDs are and why they're great. But where do we actually find them? The answer is practically everywhere! From the devices in your pockets to the appliances in your kitchen, SMDs are silently working behind the scenes to make our lives easier and more connected.

Smartphones are a prime example of SMD technology at its finest. Packed with countless components, these devices wouldn't be possible without the space-saving and performance-enhancing benefits of SMDs. From the processor and memory chips to the display driver and wireless communication modules, SMDs are essential for making smartphones the powerful and portable devices that we know and love.

Computers, laptops, tablets, and all sorts of other electronic devices also heavily rely on SMDs. From the motherboard to the graphics card, SMDs are used throughout these devices to control various functions and ensure optimal performance. Even your smart TV uses SMDs to process images, handle audio, and connect to the internet.

Beyond consumer electronics, SMDs are also used in a wide range of industrial, medical, and automotive applications. From controlling industrial robots to monitoring patients' vital signs, SMDs are essential components of many critical systems. And in the automotive industry, SMDs are used in everything from engine control units to airbag systems, ensuring the safety and reliability of modern vehicles. Even in space, satellites uses SMD that can withstand extreme condition. Impressive right?

Working with SMDs

5. Soldering Iron Required (and a Steady Hand!)

While SMDs offer many advantages, working with them can be challenging. Their small size makes them difficult to handle, and soldering them requires specialized equipment and techniques. Unless you have experience in electronics repair, it's generally best to leave SMD work to the professionals.

Soldering SMDs involves carefully placing the component onto the PCB and then using a soldering iron or hot air gun to melt solder paste, creating a secure electrical connection. It requires a steady hand, good eyesight (or a magnifying glass!), and a lot of patience. One wrong move can damage the component or the PCB, rendering the device useless.

There are plenty of excellent tutorials online demonstrating SMD soldering techniques, but don't be discouraged if it seems tricky. The key is practice and patience. But don't get discouraged if you find it challenging. Even experienced electronics technicians can struggle with SMD soldering, especially with very small components.

If you're interested in learning more about SMD soldering, there are many resources available online, including videos, tutorials, and forums. However, if you're not comfortable working with electronics, it's best to leave SMD repairs to the professionals. It's better to pay a little extra for expert service than to risk damaging your devices. Consider this to be an advanced skill level.

FAQ

6. Frequently Asked Questions about Surface Mount Devices

Still got questions about SMDs? Let's tackle some of the most common ones.

Q: Are SMDs more reliable than through-hole components?

A: Generally, yes. Because SMDs are soldered directly to the surface of the PCB, there are fewer points of failure compared to through-hole components. Also, the automated assembly process used for SMDs tends to result in more consistent and reliable connections. Less human interaction, less error happen.

Q: Can I replace a through-hole component with an SMD?

A: It's possible, but it's not always straightforward. You'll need to find an SMD equivalent of the through-hole component and then use an adapter or a custom PCB to make the connection. Also, you'll need to consider the electrical characteristics of the components to ensure that the replacement is compatible.

Q: What tools do I need to work with SMDs?

A: At a minimum, you'll need a fine-tipped soldering iron, solder paste, tweezers, and a magnifying glass. A hot air gun can also be helpful for removing and replacing SMDs. For more advanced work, you might need a microscope and specialized soldering equipment. It's really an investment, but if this is your passion, why not?

Q: How do I identify the value of an SMD resistor?

A: SMD resistors often have a three- or four-digit code printed on them that indicates their value. You can use an online SMD resistor calculator to decode the code and determine the resistance value. It's like decoding a secret message, very interesting!