Build A Info About When To Use Pi Controller

Practical No 6 Use Pi Controller To Control Temperature Of Given

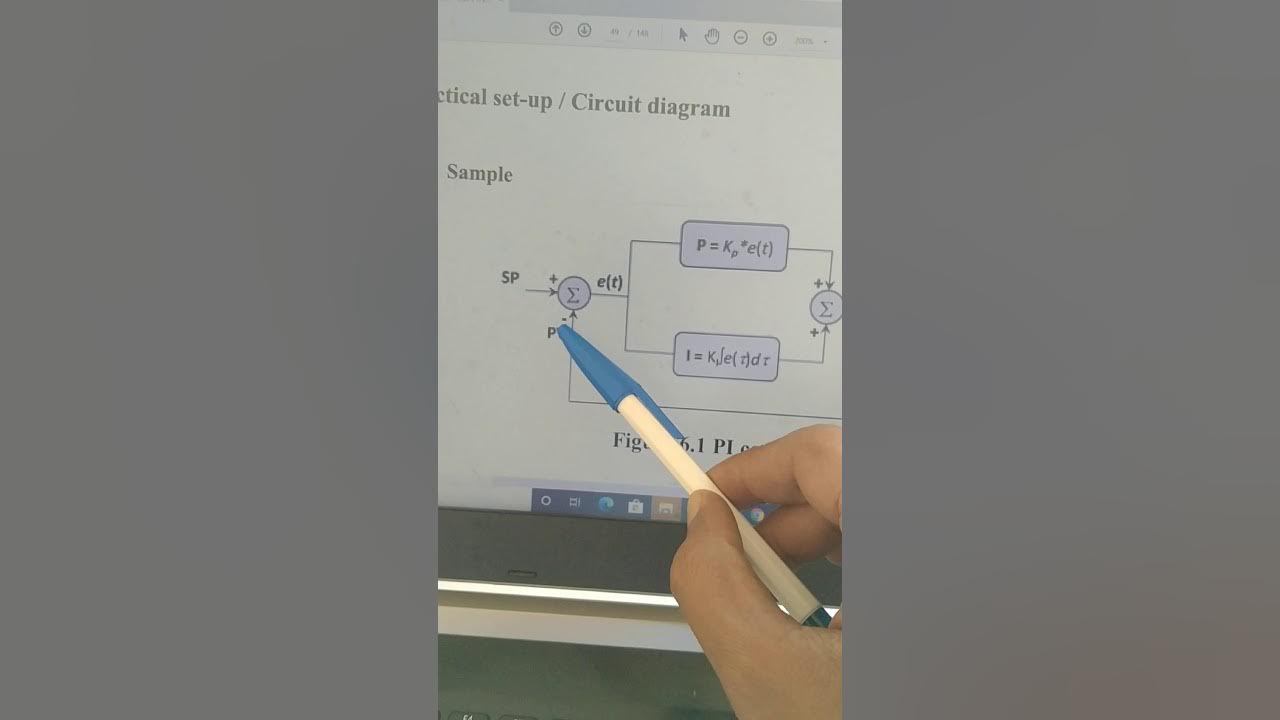

Understanding the PI Controller

1. What exactly is a PI Controller?

Alright, let's talk PI controllers! Now, before you glaze over thinking this is some super complicated engineering mumbo jumbo, think of it as a really smart thermostat. Instead of just blasting heat or AC until a certain temperature is reached, a PI controller smoothly adjusts things to get you to your desired setpoint. It uses two key ingredients: Proportional and Integral control. It's like having a chef who not only knows how much salt to add (Proportional) but also learns from past mistakes to fine-tune the seasoning for future dishes (Integral). Pretty neat, huh?

The 'P' in PI stands for Proportional. This part reacts instantly to the error between your desired outcome (setpoint) and what's actually happening. Big error? Big reaction! Small error? Small adjustment. It's a quick and responsive first step. The 'I' stands for Integral. This is where the magic happens. The Integral term looks back at past errors, figures out if there's a consistent offset, and slowly corrects for it. Imagine always undershooting your target temperature; the integral term would gradually crank things up until you finally hit the mark, removing that steady-state error.

So, why not just use a simple on-off switch? Well, that's like flooring the gas pedal every time you want to maintain a certain speed in your car — it's jerky, inefficient, and probably going to give your passengers whiplash. A PI controller, on the other hand, gently nudges the system towards the setpoint, avoiding overshoot and oscillations. Its all about smoothness and precision. These two control strategies work in harmony. The Proportional term provides the initial kick, and the Integral term cleans up any lingering errors, ensuring you reach and maintain your desired state with minimal fuss.

Think of it like steering a boat. The proportional part is like making small, immediate adjustments to the rudder based on the current course deviation. If you're way off course, you turn the rudder more aggressively. The integral part is like noticing that you consistently drift slightly to one side, so you gradually add a small, continuous correction to compensate for the drift. Together, they keep you on a steady course with minimal back-and-forth adjustments.

When to Use a PI Controller

2. Identifying the Ideal Scenarios

Okay, so when should you reach for a PI controller? The main key is when you need to maintain a stable output at a specific setpoint, and where even small inaccuracies or steady-state errors are unacceptable. Situations where precision and accuracy are paramount are where PI controllers shine. PI controllers truly excels in scenarios where you need to eliminate steady-state error. This means that the system needs to settle precisely at the desired setpoint without any persistent offset. If you're cool with a little wiggle room and don't need pinpoint accuracy, maybe a simpler control method would suffice.

Consider applications where precise temperature control is essential, such as in chemical reactors or food processing. Maintaining the correct temperature ensures that reactions proceed efficiently and products meet quality standards. Similarly, in flow control systems, PI controllers can regulate the flow rate of liquids or gases to maintain optimal performance and prevent fluctuations. Another use case is in motor speed control, where precise speed regulation is crucial for applications like robotics and automated machinery. A PI controller can ensure that the motor runs at the desired speed, even under varying load conditions.

PI controllers are also excellent for systems that experience disturbances. Let's say you're controlling the water level in a tank. If someone suddenly starts drawing water from the tank, a PI controller will automatically compensate for the disturbance and maintain the water level at the setpoint. The integral term is particularly helpful in these situations, as it continuously corrects for any persistent deviations caused by the disturbance. Think about a cruise control system in a car, for example. The PI controller adjusts the throttle to maintain the desired speed, even when encountering hills or headwinds.

However, before jumping straight to implementing a PI controller, there are few things to consider. If your system doesnt require tight regulation or doesnt suffer from steady-state errors, it might be an overkill. Simpler systems can often be controlled perfectly well with simpler methods. Also, the system you are controlling needs to be stable. PI controllers wont fix an inherently unstable system and can even make it worse. If that is the case, you might need more advanced control methods, or even to redesign the system.

Situations Where PI Controllers Might Not Be the Best Choice

3. Recognizing the Limitations

Now, even though PI controllers are amazing, they are not always the best solution for every situation. For instance, if your system needs really fast response times, a PI controller might not be the quickest option. It takes time for the integral term to wind up and correct for errors, so it can be a bit sluggish in certain cases. So, imagine trying to catch a ball, if you were to control your arm with a PI controller, you might miss the catch, as the action requires a swift response.

Another scenario where PI controllers might struggle is with highly nonlinear systems. Think of a system where the response changes drastically depending on the input. In these cases, the fixed gains of a PI controller might not be able to handle the varying dynamics effectively. You might need more advanced control techniques, such as adaptive control or model predictive control, that can adjust to the changing behavior of the system. A great example is controlling the flight of a drone, where the aerodynamics change significantly at different speeds and angles of attack.

Furthermore, if your system is inherently unstable, adding a PI controller won't magically fix the instability. It can even make things worse! PI controllers are designed to fine-tune stable systems, not to stabilize inherently unstable ones. In such cases, you might need to redesign the system to improve its stability or use more sophisticated control methods that can actively stabilize the system. Imagine trying to balance a broomstick on your hand. If the broomstick is inherently unstable (which it is!), a PI controller won't be able to keep it upright for long. You'd need to actively move your hand to counteract the instability.

Finally, implementing a PI controller requires careful tuning. You need to choose the right values for the proportional and integral gains to achieve optimal performance. If the gains are not properly tuned, the system can become unstable or oscillate wildly. Tuning a PI controller can be time-consuming and requires a good understanding of the system dynamics. There are various methods for tuning PI controllers, such as the Ziegler-Nichols method or the Cohen-Coon method, but they all involve some trial and error. Consider a sound system. If you don't tune it properly, the speakers can oscillate, leading to distorted audio.

Pi Pico Relay With Arduino Code Control AC Appliances

Practical Examples of PI Controller Applications

4. Real-World Scenarios Where PI Controllers Excel

So, where can you find PI controllers in the wild? Everywhere! Seriously. They're the unsung heroes behind countless everyday technologies. Let's start with temperature control. Think about your home thermostat. It's a classic example of a PI controller at work. It continuously monitors the room temperature and adjusts the heating or cooling system to maintain the setpoint. Without a PI controller, your home would likely be either too hot or too cold, with frequent temperature swings.

Next up, consider the cruise control in your car. It uses a PI controller to maintain a constant speed, even when you're going uphill or downhill. The controller adjusts the throttle to compensate for changes in road grade and wind resistance, ensuring a smooth and consistent driving experience. The proportional part reacts immediately to speed deviations, while the integral part eliminates any steady-state error, such as slowing down on a long uphill climb. These are the kind of applications you have on your hands every single day.

Let's move on to industrial processes. PI controllers are widely used in manufacturing plants to control various parameters, such as pressure, flow, and liquid level. For example, in a chemical plant, a PI controller might regulate the flow rate of reactants into a reactor to ensure that the reaction proceeds at the desired rate. In a water treatment plant, a PI controller might maintain the water level in a storage tank. The robustness and reliability of PI controllers make them ideal for these critical applications. Without proper control, the manufacturing process could easily go haywire, resulting in wasted resources, defective products, or even safety hazards.

Finally, PI controllers are also used in robotics and automation. They're essential for precise motor control, enabling robots to perform complex tasks with accuracy and repeatability. For example, a PI controller might be used to control the position of a robotic arm, ensuring that it moves to the correct location with minimal overshoot or oscillations. In automated manufacturing, PI controllers are used to control the speed and position of conveyor belts, ensuring that parts are moved smoothly and accurately between different stations. There are so many possibilities that PI controllers can be used for.

Figure 1 From Double ClosedLoop PI Control Of ThreePhase Inverters By

Tuning Your PI Controller

5. Achieving Optimal Performance

Alright, you've got your PI controller set up, but it's not quite behaving as you expected. Don't worry, tuning a PI controller is an art, not a science! It involves finding the right balance between the proportional and integral gains to achieve optimal performance. Lets start with the Proportional gain. Increasing the P gain will increase the speed of your response to deviations. However, a P gain thats too high can cause oscillations and even instability.

Next up, the Integral gain. The I gain helps eliminate steady-state error, but increasing it too much can lead to slow oscillations and sluggish response. The key is to find a balance where the integral term corrects for errors quickly without causing excessive overshoot or instability. Consider a car's cruise control system again. If the integral gain is too high, the car might constantly speed up and slow down as it tries to maintain the set speed. If it's too low, the car might consistently run slightly below the set speed on a long uphill climb.

There are several methods for tuning PI controllers, such as the Ziegler-Nichols method and the Cohen-Coon method. These methods involve performing experiments on the system and using the results to calculate the appropriate gain values. However, these methods are often just a starting point, and you might need to fine-tune the gains based on your specific application and requirements. So, imagine tuning a musical instrument. You wouldn't just rely on a tuning fork to get it perfect. You'd also listen to the sound and make adjustments based on your ear.

Lastly, don't be afraid to experiment! Tuning a PI controller is often an iterative process. Start with conservative gain values and gradually increase them until you achieve the desired performance. Keep a close eye on the system's response and watch out for signs of instability, such as oscillations or overshoot. If you encounter any problems, reduce the gains and try again. Remember, the goal is to find the sweet spot where the PI controller provides fast, accurate, and stable control. If you persist and practice, you will become a master of PI controllers.

Closedloop Control Of Buck Converter Using PI Controller. Download