Beautiful Info About Who Uses Bill Of Materials

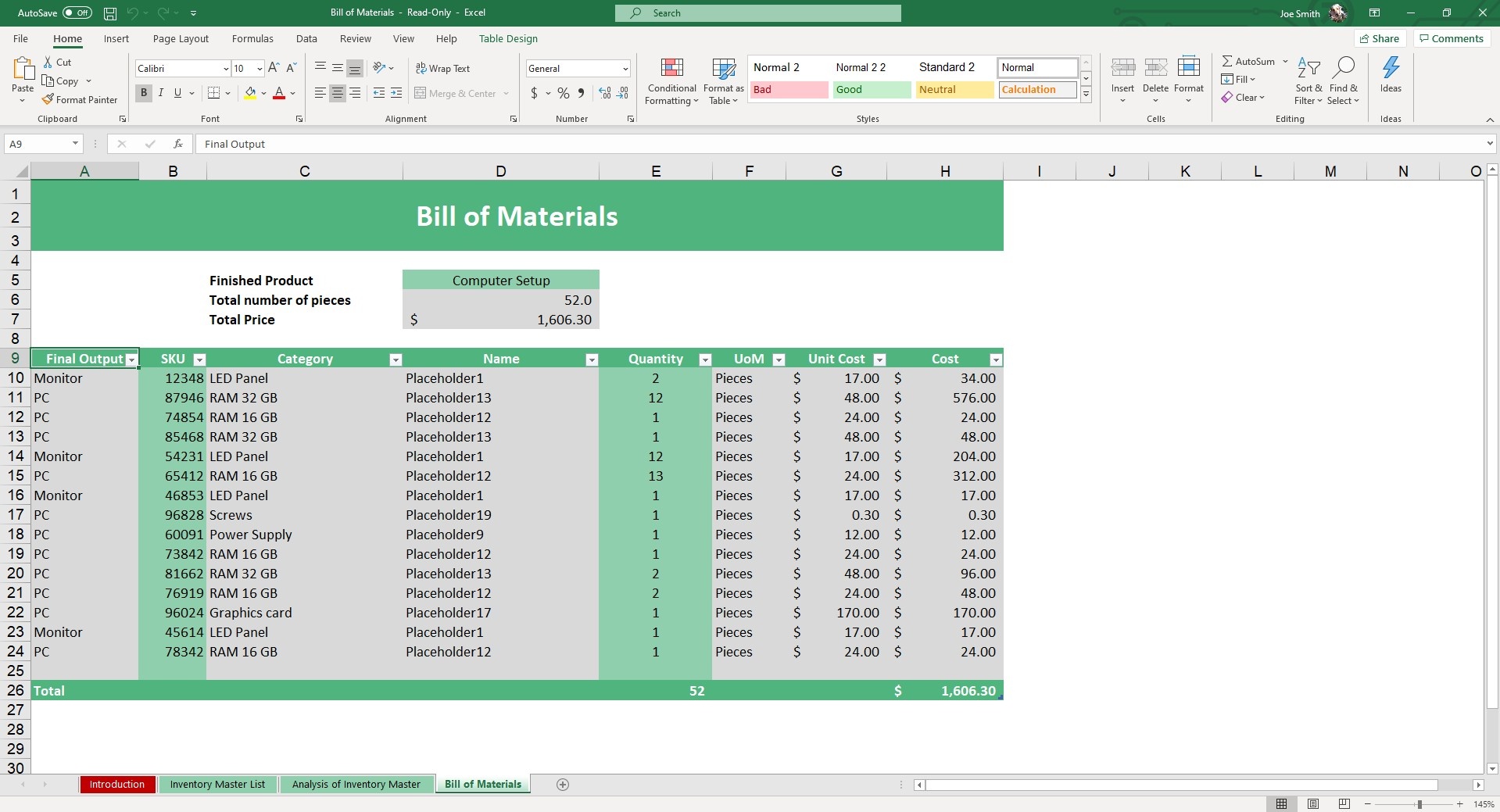

FREE Bill Of Materials Excel & Google Sheets Template Simple

Unlocking the Secrets of the Bill of Materials

1. Demystifying the Bill of Materials

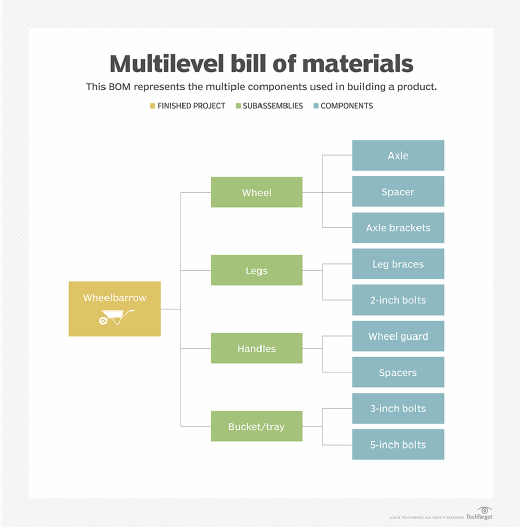

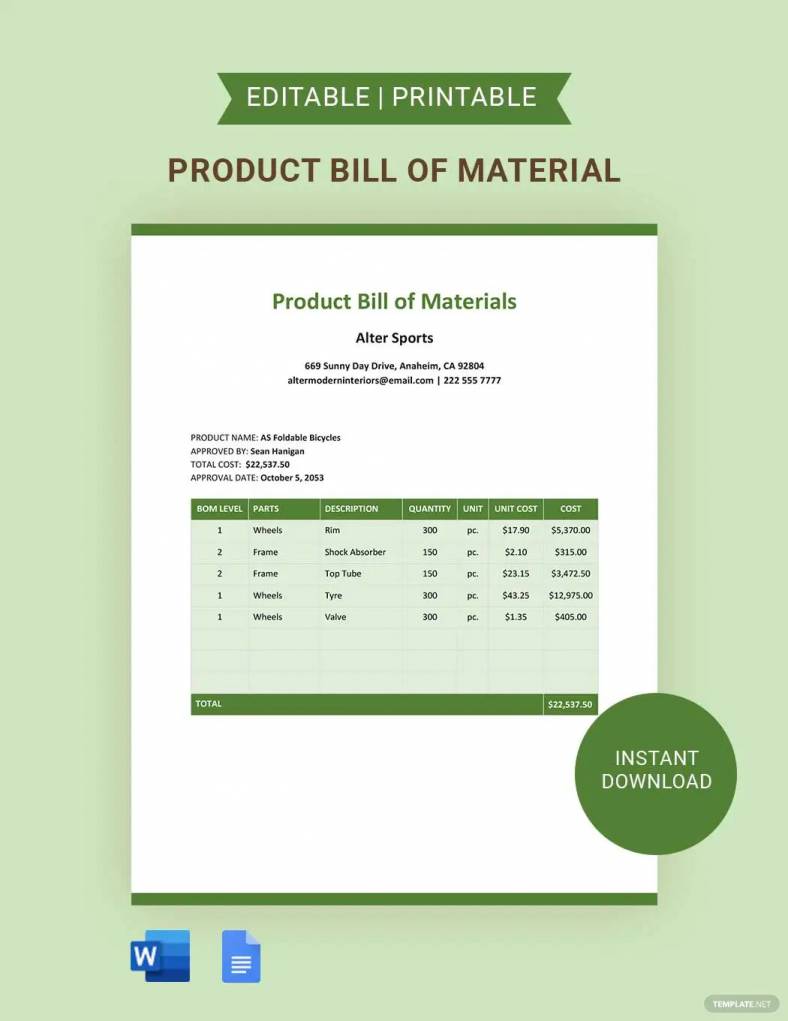

Ever wondered what a Bill of Materials (BOM) actually is? Think of it as a recipe, but instead of cookies, you're baking well, pretty much anything from a bicycle to a Boeing 747. A BOM is a comprehensive list of all the raw materials, sub-assemblies, parts, and quantities needed to manufacture an end product. It's the blueprint for production, ensuring everyone is on the same page, using the right ingredients, and building things correctly. It's more than just a list; it's a central nervous system for manufacturing.

So, who exactly relies on this crucial document? You might be surprised by the variety of industries and roles that find the BOM indispensable. Let's dive into the world of BOM users and uncover why this document is so vital to their success. Because honestly, without it, things could get pretty chaotic. Imagine trying to build a car without knowing how many tires you need. Yikes!

The beauty of a well-structured BOM lies in its ability to bring clarity and order to complex manufacturing processes. Its not just about listing parts; its about defining relationships between them, specifying quantities, and even including instructions for assembly. Think of it as the ultimate cheat sheet for creating something tangible, whether its a simple widget or a sophisticated piece of machinery. This level of detail reduces errors, improves efficiency, and ultimately saves time and money.

And just to be clear, a BOM isn't just a static document. It's dynamic, evolving as designs change and improvements are made. Managing these changes effectively is crucial, requiring version control and clear communication between different teams. The BOM is the single source of truth for all things related to a product's composition, ensuring that everyone from engineers to procurement specialists is working with the most up-to-date information. No more guessing games!

The Engineers' Best Friend

2. How Engineers Use BOMs

For design and engineering teams, the BOM is more than just a list; its a foundational document that shapes the entire product development process. Engineers use the BOM to define the components of a product during the design phase, ensuring that everything fits together correctly and meets performance requirements. It's the digital equivalent of a meticulously crafted Lego set instruction manual, only far more complex.

The BOM allows engineers to visualize the product's structure, identify potential design flaws, and optimize material usage. They can use it to evaluate the cost implications of different design choices and make informed decisions about which components to use. Think of it as a digital playground where they can experiment and iterate without having to physically build prototypes every time. A good BOM enables quicker and more efficient innovation.

Furthermore, the BOM serves as a critical communication tool between different engineering disciplines. Mechanical engineers can use it to specify the physical dimensions and materials of components, while electrical engineers can use it to define the electronic components and wiring. This collaboration ensures that the final product is a harmonious blend of form and function. It also reduces the risk of costly errors down the line.

And let's not forget about change management. Engineering changes are inevitable, and the BOM provides a structured way to track these changes and ensure that everyone is working with the latest version. This is particularly important in industries where products are constantly evolving and improving. Imagine trying to keep track of changes to a complex product without a central, up-to-date BOM. It would be a recipe for disaster.

Procurement Pros

3. BOMs and Procurement

Procurement teams rely heavily on the BOM to understand the exact quantities and specifications of materials required for production. Armed with this information, they can source the right components from the right suppliers at the best possible prices. Think of them as the shoppers of the manufacturing world, always on the lookout for the best deals and the highest quality ingredients. But instead of groceries, they're buying nuts, bolts, and circuit boards.

The BOM enables procurement teams to plan their purchasing activities effectively, ensuring that materials are available when needed to avoid production delays. They can use the BOM to forecast demand, negotiate contracts with suppliers, and manage inventory levels. It's like having a crystal ball that allows them to see into the future and anticipate material needs. Without a BOM, they'd be flying blind, leading to stockouts or overstocking.

Moreover, the BOM facilitates collaboration between procurement and other departments, such as engineering and production. Procurement can provide feedback on material availability and lead times, while engineering can provide updates on design changes that may affect material requirements. This collaborative approach ensures that the supply chain is aligned with the overall production plan. It's a symphony of teamwork, all orchestrated by the BOM.

The accuracy of the BOM is paramount for procurement. Inaccurate or incomplete BOMs can lead to incorrect orders, production delays, and increased costs. Therefore, procurement teams often work closely with engineering and manufacturing to validate the BOM and ensure that it reflects the true material requirements. After all, a mistake on the BOM can have ripple effects throughout the entire supply chain. It pays to get it right.

Manufacturing Masters

4. Manufacturing and the Bill of Materials

For manufacturing teams, the BOM is the ultimate guide to assembling the product. It provides detailed instructions on how to put everything together, step-by-step. Think of it as the assembly manual for a complex piece of furniture, but with far more moving parts and technical specifications. It ensures that every product is built consistently and according to the design specifications.

The BOM helps manufacturing teams to optimize the production process, identify potential bottlenecks, and improve efficiency. They can use it to track material consumption, monitor inventory levels, and identify areas where waste can be reduced. It's like having a GPS for the production floor, guiding them along the most efficient route. Without a BOM, the production process would be a chaotic mess.

Furthermore, the BOM facilitates communication between different teams on the manufacturing floor. Assembly workers can use it to understand the sequence of operations, while quality control inspectors can use it to verify that the product meets the required standards. This collaboration ensures that everyone is working towards the same goal. It's a well-oiled machine, all thanks to the BOM.

The BOM is also crucial for managing changes during the production process. If a component needs to be substituted or modified, the BOM can be updated to reflect these changes. This ensures that the production team is always working with the most up-to-date information. It's like having a real-time instruction manual that adapts to changing circumstances. This level of flexibility is essential for maintaining production efficiency and quality.

Bill Of Materials Is Another Name For A Parts List. Notebase

Beyond the Core Teams

5. Who Else Benefits from a BOM?

While engineering, procurement, and manufacturing are the primary users of the BOM, other stakeholders also benefit from having access to this information. For example, customer service teams can use the BOM to understand the components of a product and troubleshoot issues more effectively. They can quickly identify the parts that may be causing a problem and provide accurate information to customers.

Sales and marketing teams can use the BOM to understand the cost structure of a product and develop pricing strategies. They can also use it to highlight the unique features and benefits of a product to potential customers. It's like having a secret weapon that allows them to sell the product more effectively. A well-informed sales team is a successful sales team.

Finance teams can use the BOM to track the cost of goods sold and manage inventory valuation. They can use it to analyze the profitability of different products and make informed decisions about resource allocation. It's like having a financial blueprint that guides their decision-making process. Without a BOM, financial planning would be a shot in the dark.

Even regulatory compliance teams can benefit from the BOM. It can be used to track the materials used in a product and ensure that they meet environmental and safety regulations. This is particularly important in industries where products are subject to strict regulatory requirements. It's like having a compliance checklist that ensures the product meets all the necessary standards. A BOM helps companies avoid costly penalties and maintain their reputation.

FAQ

6. Frequently Asked Questions

Q: What's the difference between a BOM and a parts list?

A: Think of a parts list as a simple list of ingredients. A BOM is the full recipe, including quantities, relationships between parts, and even assembly instructions! It's far more comprehensive.

Q: Can a BOM be used for services, not just products?

A: Absolutely! While typically associated with manufactured goods, a BOM concept can be adapted for service-based businesses, outlining the resources, steps, and dependencies involved in delivering a particular service. It helps standardize service delivery and improve efficiency, just like in manufacturing.

Q: What are the different types of BOMs?

A: There are a few main types, including: Engineering BOM (EBOM): Focuses on the design perspective. Manufacturing BOM (MBOM): Focuses on the assembly process. * Sales BOM (SBOM): Focuses on how the product is sold (e.g., kits or bundles).Each serves a slightly different purpose, tailored to the needs of different departments.

Q: Is a BOM just for large companies?

A: Not at all! While large companies definitely benefit, even small businesses can use a simplified BOM to manage their inventory and production more effectively. It's all about scaling the tool to fit your needs.