Smart Tips About What Is The Job Description Of A BOM

Expand Your Skills In Drafting & Design Ppt Download

Decoding the BOM

1. Breaking Down the BOM Role

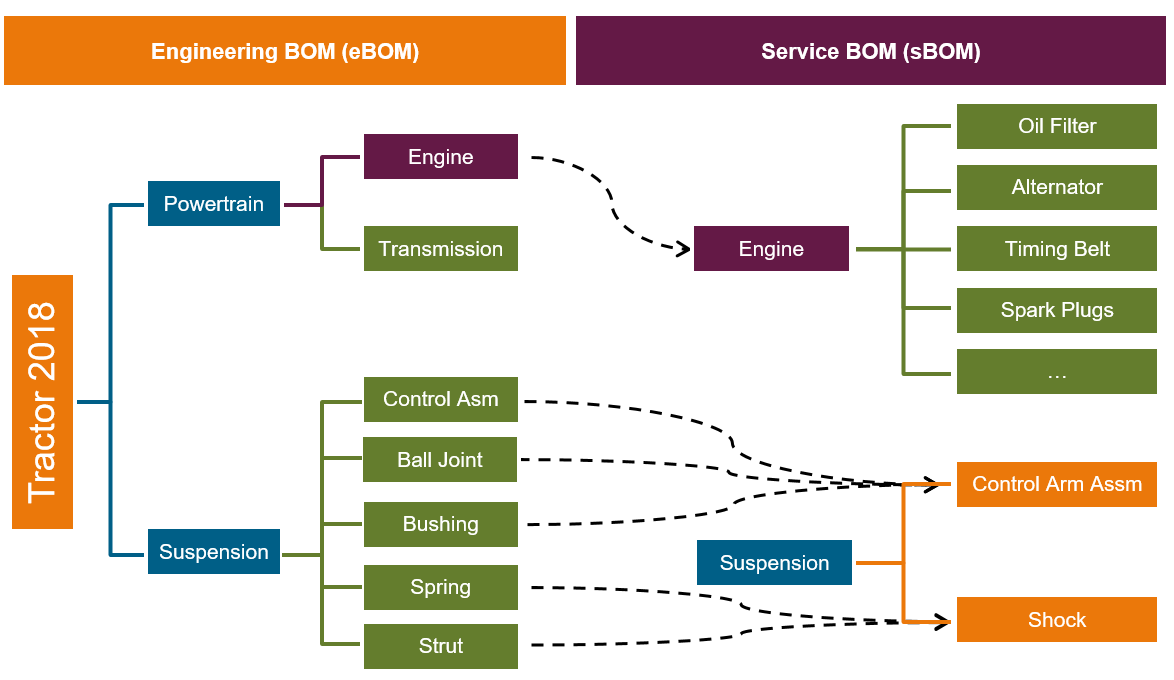

Ever heard someone mention a BOM and thought, "Bill of Materials... okay, but what does that person do?" You're not alone! The job description of a BOM, or Bill of Materials specialist (the keyword term we're focusing on here, and yes, it's primarily a noun, referring to the role itself or the person holding it), can be a bit of a mystery. It sounds technical, and well, it is, but it also involves a surprising amount of communication and problem-solving. Think of them as the linchpin between design, engineering, purchasing, and manufacturing.

The BOM specialist's main gig is to create and maintain the Bill of Materials. Now, a Bill of Materials is essentially a comprehensive list of all the raw materials, components, and assemblies required to manufacture a product. Imagine building a Lego castle; the BOM is the instruction manual listing every brick, window, and tiny knight you need. Without it, chaos ensues!

But it's not just about listing things. The BOM specialist ensures the accuracy and completeness of that list, working with engineers to understand design changes, collaborating with purchasing to confirm availability and pricing, and communicating with manufacturing to ensure they have everything they need to build the product correctly. Its a delicate balancing act, juggling technical details with practical considerations.

And speaking of balancing acts, they often need to manage multiple BOMs for different product versions, configurations, or manufacturing locations. Talk about keeping a lot of plates spinning! So, while the initial perception might be of someone glued to a spreadsheet, the reality involves a lot of collaboration, communication, and critical thinking.

BOM Responsibilities

2. Delving Deeper into the Daily Grind

Alright, so you've got the gist of what a Bill of Materials is. Now, let's dig into the specific responsibilities that fall under the job description of a BOM specialist. It's more varied than you might think!

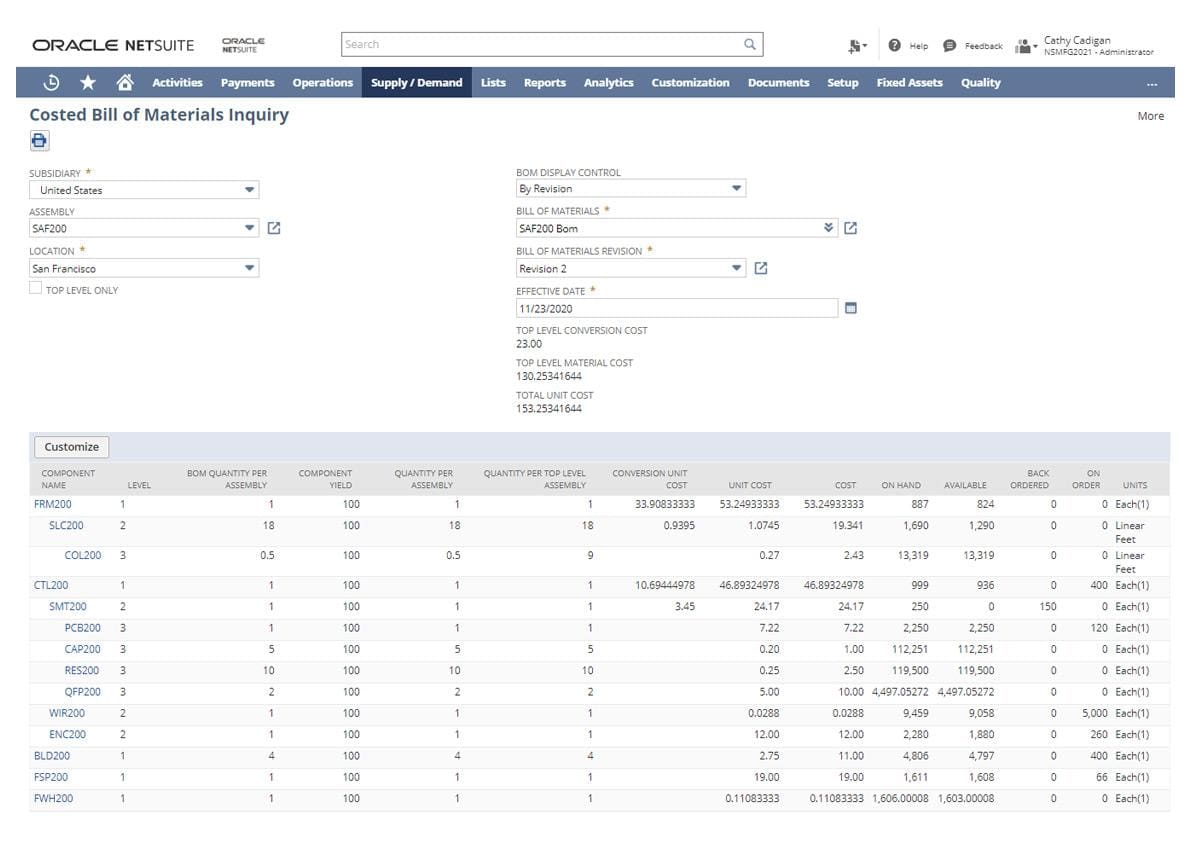

First and foremost is BOM creation and maintenance. This involves working closely with design and engineering teams to understand the product's components and structure. They input all this information into a system (usually a PLM or ERP system), ensuring everything is accurately described, specified, and linked. This isn't a one-time thing, either. As the product design evolves, the BOM specialist must keep the BOM updated, reflecting any changes or revisions.

Another crucial responsibility is ensuring data accuracy. Incorrect or incomplete BOM data can lead to production delays, material shortages, and even product defects. The BOM specialist acts as a gatekeeper, verifying the accuracy of part numbers, descriptions, quantities, and specifications. They might also be responsible for implementing data validation rules and processes to prevent errors from creeping in.

Furthermore, they often collaborate with purchasing and supply chain teams to ensure materials are available when needed. This might involve checking inventory levels, coordinating with suppliers, and resolving any material-related issues that arise during the manufacturing process. Think of them as the "supply chain whisperer," anticipating potential problems before they become full-blown crises.

Beyond these core tasks, BOM specialists might also be involved in cost analysis, helping to identify opportunities to reduce material costs. They might also participate in continuous improvement initiatives, streamlining BOM processes and improving data quality.

Skills and Qualifications

3. The BOM Specialist Toolkit

So, you're thinking of pursuing a career as a BOM specialist? Excellent choice! But what skills and qualifications do you need to succeed? Let's unpack that. The job description of a BOM often calls for a mix of technical know-how and soft skills.

On the technical side, a solid understanding of manufacturing processes and materials is essential. You don't need to be a master machinist, but you should have a good grasp of how things are made and what materials are commonly used. Familiarity with engineering drawings and CAD models is also a plus. And, of course, proficiency with PLM (Product Lifecycle Management) or ERP (Enterprise Resource Planning) systems is a must-have. These are the tools of the trade!

But technical skills alone aren't enough. Strong analytical and problem-solving abilities are crucial. You'll need to be able to analyze complex BOM structures, identify discrepancies, and troubleshoot material-related issues. Attention to detail is also paramount. A single typo in a part number can have disastrous consequences, so you need to be meticulous and accurate.

And let's not forget the soft skills. Excellent communication and collaboration skills are essential. You'll be working with people from different departments, so you need to be able to communicate technical information clearly and concisely, both verbally and in writing. You'll also need to be a good listener and a team player.

In terms of education, a bachelor's degree in engineering, manufacturing technology, or a related field is often preferred. However, some companies may consider candidates with an associate's degree or equivalent experience. Certifications in areas like BOM management or PLM systems can also be valuable.

What Is BOM? BOM Types And Formats

The BOM's Impact

4. The Ripple Effect of a Well-Managed BOM

Okay, so we know what a BOM specialist does, but why is this role so important? The job description of a BOM specialist might sound like a lot of tedious paperwork, but the impact of their work extends far beyond spreadsheets and databases. A well-managed BOM is the foundation of efficient manufacturing, cost control, and product quality. It can make or break a company's success.

A precise and accurate BOM ensures that the right materials are available at the right time, preventing production delays and material shortages. This, in turn, helps companies meet customer demand and avoid costly downtime. Think of the BOM as the conductor of an orchestra, ensuring that all the different instruments (materials, components, processes) come together in harmony.

Moreover, a well-maintained BOM facilitates cost control. By accurately tracking material costs, companies can identify opportunities to reduce expenses and improve profitability. The BOM specialist can help negotiate better pricing with suppliers, optimize material usage, and identify alternative materials that can lower costs without compromising quality.

And let's not forget about product quality. A BOM that specifies the correct materials and components ensures that the final product meets the required specifications and performance standards. This, in turn, enhances customer satisfaction and reduces the risk of product defects or recalls. After all, nobody wants a faulty widget because someone entered the wrong part number!

What Exactly Is A Bill Of Materials Bom Electrical Engineering Images

Beyond the Basics

5. Evolving with Technology and Industry Trends

The role of the BOM specialist isn't static. It's constantly evolving in response to technological advancements and changing industry trends. The job description of a BOM is expanding to encompass new responsibilities and challenges. Let's take a peek at what the future might hold.

One major trend is the increasing use of digital tools and technologies, such as artificial intelligence (AI) and machine learning (ML). These technologies can automate many of the manual tasks associated with BOM management, such as data entry, error detection, and BOM comparison. AI can also be used to predict material demand, optimize inventory levels, and identify potential supply chain disruptions.

Another important trend is the growing emphasis on sustainability and circular economy principles. Companies are increasingly focused on reducing their environmental impact and minimizing waste. The BOM specialist can play a key role in this effort by identifying opportunities to use recycled materials, design products for disassembly and reuse, and optimize material usage to minimize waste.

Furthermore, the rise of Industry 4.0 and smart manufacturing is transforming the way products are designed, manufactured, and serviced. The BOM specialist will need to be able to integrate BOM data with other manufacturing systems, such as MES (Manufacturing Execution Systems) and ERP systems, to enable real-time monitoring and control of production processes.

In short, the future of the BOM role is bright. As companies embrace new technologies and strive to become more efficient and sustainable, the BOM specialist will become an even more valuable asset. So, if you're looking for a challenging and rewarding career, consider becoming a BOM whiz!